Poultry Feed Ingredient Costs Per Cwt

Increasing ingredient costs have wreaked havoc across the dairy industry, leading to elevated ration costs not seen in many years. Feed costs per pound of dry matter are rising as much as 20% or more as corn and soybean meal prices climb, minimizing farmers' profit margins. While some producers were fortunate enough to have protected their operations through contracted ingredient pricing prior to the ingredient pricing climb, others are looking for ways to implement cost-saving measures to minimize the high-cost burden of current market feed prices. Outlined below are several factors to consider to help improve your ration economics while maintaining milk yield.

Corn grain, whole soybeans, soybean meal, distillers' grains and quality hay prices are all on the rise. Corn grain and whole soybeans recently reached cost-per-bushel prices not seen since 2013. Soybean meal prices have followed suit, with their highest price per ton since 2014. The current forecasted planting estimates are 1–8% higher than 2020's planted acres, with better-than-average commodity prices expected at harvest. While high commodity prices are great for those producers who can raise more than what they need on the farm, producers who rely on purchasing commodities as ration ingredients are currently facing tough decisions.

Even though feed prices are increasing, some things will never change. Dairy cows still require amino acids, glucose, energy and fatty acids to produce milk and milk components and to maintain fertility. High-production cows still have the opportunity to be profitable, so we do not want to make changes to high-producing cows' rations that will limit their production potential.

High corn prices

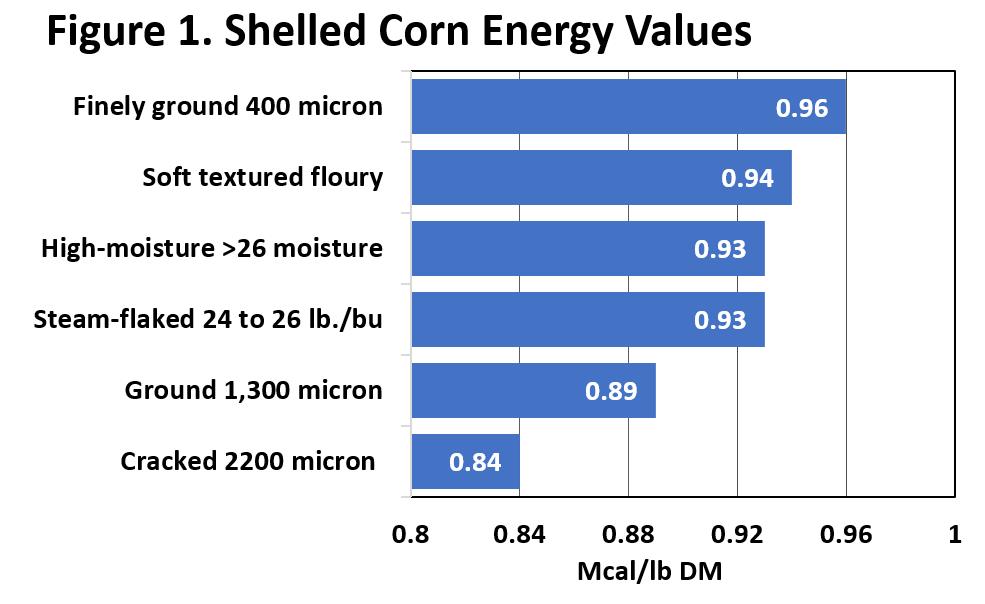

Corn grain is one of the toughest ingredients to replace in typical midwestern rations due to the high level of starch density/energy it delivers for the cost compared to other starch sources. Even at the recent high prices, corn grain still delivers the best bang for your buck when evaluating energy sources. If you haven't recently, now is the time to evaluate your ground-corn micron size, with the goal of achieving an average of 400 microns (Figure 1) to maximize the utilization of corn delivered while potentially reducing the amount of corn grain needed in the ration.

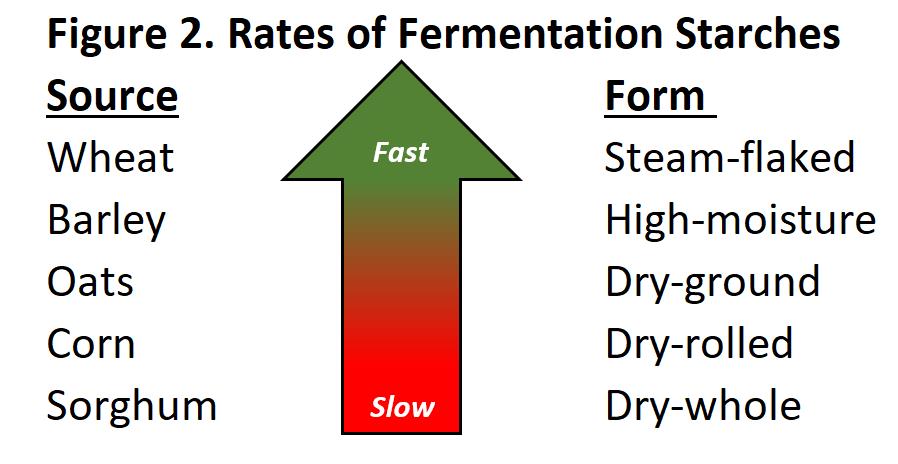

Another area to evaluate is your corn silage starch level and digestibility. Corn silage starch digestibility levels increase while in storage and should be close to achieving their maximum level of digestibility in the spring. If your corn silage is now supplying more fermentable starch to the ration, you may be able to reduce the amount of corn grain going into your ration. If your current corn silage inventory is greater than usual for this time of year, you may be able to push your corn silage inclusion to help reduce your corn grain inclusion, while being careful to not drastically increase your ration fiber level. Other ingredients to consider when trying to offset the use of corn grain include barley, oats, wheat, sorghum, hominy, bakery byproduct and cereal byproduct. It is important to keep in mind that these commodities ferment at different speeds, as is indicated in Figure 2. Additionally, sugar and fat sources can help to offset starch energy sources, if the economics allow. Working with your nutritionist to determine the ingredient availability and cost per ton versus the energy contribution to the ration will help producers determine the appropriate ingredient selection for their operation.

High protein prices

With protein ingredient prices continuing to climb, evaluating and comparing protein sources based on their value for the money is essential. However, not all proteins are considered equal. While soybean meal is a staple in many midwestern diets, other protein sources can help fill the gaps when necessary. When determining what protein ingredients are needed, it is important to first assess your on-farm forages and home-grown concentrates, with the goal of only purchasing what you need to complement your base ration. Commonly, purchased proteins are a balance of rumen-degradable protein and rumen-undegradable sources, which, when properly selected, can enhance the amino acid profile of the ration, depending on their respective lysine and methionine percentages. When evaluating protein sources, it is important to first compare the cost per unit of protein delivered by each source, knowing that dense protein products will more easily allow you to maximize your homegrown forages.

When optimizing your rations, it is crucial to evaluate the diet for metabolizable protein. Metabolizable protein is the total amount of amino acids available in the small intestine for absorption by the cow. It is made up of microbial protein being synthesized from rumen-degradable sources (typically 60–75%) and rumen-undegradable protein added to the diet to provide the remaining need and further fuel animal performance. If dietary soluble protein levels are low (i.e., less than 30% of the diet dry matter), sustained-release urea — such as that included in Optigen — can be a great addition to help enhance the soluble protein with the goal of maximizing efficient microbial growth and can also aid in reducing purchased feed costs.

Focus on forage quality

Maximizing NDF digestibility and protein in this year's forage crop could help dramatically reduce your purchased feed costs throughout the coming year. When highly digestible forages are fed, less concentrate is required in the ration to achieve optimal performance. Consider forage hybrids that are "low lignin" and that have a higher total tract NDF digestibility, leading to greater digestibility at a faster rate. Additionally, maximizing your corn silage inclusion based on your inventory will allow your farm to achieve the desired starch level while minimizing the amount of purchased starch. Ensuring that you are planting corn silage varieties that, when harvested, can achieve an NDF 30-hour digestibility of 60% NDF or higher while maintaining adequate starch will allow you to feed higher corn silage levels in the ration. Failure to plan for adequate forage inventories at planting can lead to drastic increases in purchased feed costs later, if additional ration ingredients are needed to compensate.

Other considerations

- Carefully evaluate the economic impact of reducing corn/starch and/or protein supplements in your rations prior to making any changes.

- Do not give up milk yield or milk components, as this will drastically impact your bottom line.

- Evaluate alternative sources of energy using fermentable carbohydrates as an opportunity to adjust levels.

- Rely on your nutritionist to predict the impact that a change in protein sources will have on your animals' performance (e.g., RDP vs. RUP vs. amino acids), and continue to monitor MUN values.

- Consider culling cows or drying cows up early (e.g., those who are not currently paying for themselves with lower levels of milk production).

- Enhance protocols to minimize on-farm feed shrink and optimize your feed bunk management strategies.

- Continue to calculate feeding economic values, such as the ones below, to ensure that you will remain profitable in the coming year:

- Income over feed costs

- Feed costs per pound of dry matter intake

- Feed costs per cwt of milk

- Feed efficiency

- Component efficiency

Taking a guided and thought-out approach to forecasting potential feed ingredient changes can help ensure that you will have efficient milk production moving forward. Please reach out to your local Hubbard Dairy representative to discuss your goals, and in partnership, we can help you create a plan for success.

christensonreeas1974.blogspot.com

Source: https://www.hubbardfeeds.com/blog/evaluating-feed-costs-during-times-high-commodity-prices

Post a Comment for "Poultry Feed Ingredient Costs Per Cwt"